Drythane 100 % Solids Liquid Applied Two Component Polyurethane Waterproofing

Price 110.0 INR/ Kilograms

MOQ : 100 Liters

Drythane 100 % Solids Liquid Applied Two Component Polyurethane Waterproofing Specification

- Usage & Applications

- Industrial & Commercial

- Purity

- High

- Water Absorption

- Yes

- Chemical Form

- Liquid

- Type

- Polyurethane Waterproofing

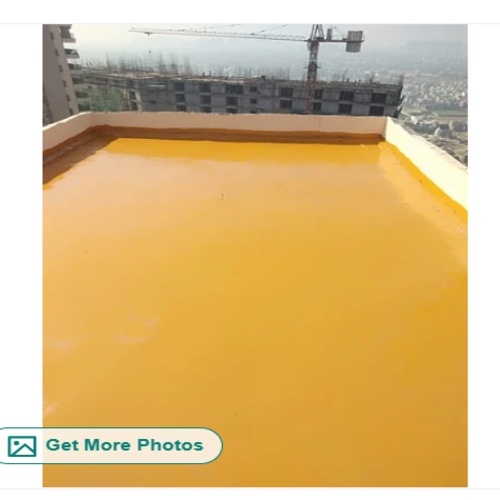

- Color

- Yellow

Drythane 100 % Solids Liquid Applied Two Component Polyurethane Waterproofing Trade Information

- Minimum Order Quantity

- 100 Liters

- Delivery Time

- 7 Days

About Drythane 100 % Solids Liquid Applied Two Component Polyurethane Waterproofing

Drythane coatings are 100% Solids (Solvent Free) twocomponent Polyurethane & Hybrid Polyurea Coatingsystems that contains no solvents, noxious smells andare non-flammable. They have been formulatedspecifically as high performance waterproofingmembranes.Drythane provides lifelong protection to concrete andother masonry. Once coated, the surface is completelyimpervious to water. With Drythane, you can creategreen and cool roofs of your dreams, with gardens,vegetation, water bodies, swimming pools etc.Applied as a thick film (1.20 - 2.00 mm), these premium,high performance products have an expected service lifeof 30 years and moreSuperior Polyurethane Protection

Drythanes advanced two-component polyurethane technology forms a durable, elastic membrane that effectively resists water penetration. Its 100% solids composition means superior coverage and longevity, making it suitable for demanding industrial and commercial environments where traditional waterproofing may fail.

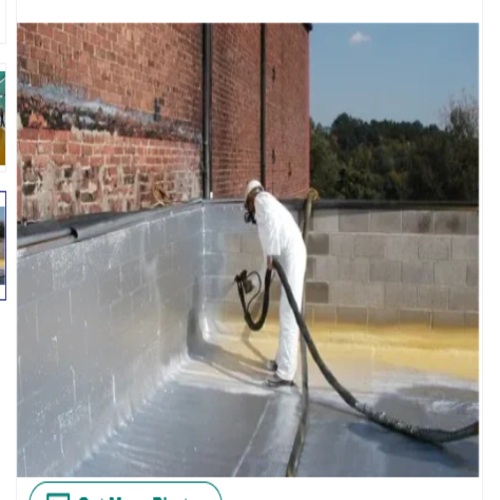

Effortless Application Process

This waterproofing system is applied as a liquid, which allows for seamless coverage over complex surfaces and details. The two liquid components are mixed and spread, ensuring rapid curing and minimal downtime. With its targeted formulation for Indian conditions, Drythane streamlines large-scale waterproofing projects efficiently.

FAQs of Drythane 100 % Solids Liquid Applied Two Component Polyurethane Waterproofing:

Q: How is Drythane 100% Solids Polyurethane Waterproofing applied?

A: Drythane is applied by combining its two liquid components, then spreading the mixture evenly onto the prepared surface. The product is designed for ease of use, allowing it to conform seamlessly to varied surface profiles and providing a uniform, durable barrier against water infiltration.Q: What makes Drythane suitable for both industrial and commercial applications?

A: Drythane is engineered with high purity and durability, making it ideal for both industrial and commercial settings. Its robust, flexible membrane withstands heavy use, exposure to chemicals, and fluctuating environmental conditions commonly found in these environments.Q: When should Drythane waterproofing be used in a construction project?

A: Drythane should be used during the construction phase or during renovation whenever reliable, long-term waterproofing is critical. It is particularly beneficial for areas exposed to constant moisture such as roofs, basements, water tanks, and industrial floors.Q: Where can Drythane be sourced in India?

A: Drythane is available throughout India via reputable exporters, suppliers, and traders who specialize in advanced construction chemicals and waterproofing solutions. It can be easily procured for both large-scale and specialized projects.Q: What is the process for ensuring proper water absorption control with Drythane?

A: After thorough surface preparation and correct mixing of the two liquid components, Drythane creates a highly impermeable layer. This layer significantly limits water absorption, thus effectively safeguarding the underlying structure against moisture damage.Q: How does using Drythane benefit long-term durability of structures?

A: By forming a continuous, high-strength membrane, Drythane greatly enhances the longevity of building elements. Its chemical resistance, flexibility, and zero seams help prevent deterioration from water, ultimately reducing maintenance needs and costs.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Waterproofing Products Category

Sikadur 55 LP IN

Price 2200.0 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Usage & Applications : Construstions

Color : pale yellow

Chemical Form : Waterproofing

Purity : Sikadur 55 LP IN has a purity of 98%,

Ditchtament DS2

Price 120 INR / Kilograms

Minimum Order Quantity : 10 Kilograms

Usage & Applications : Waterproofing

Color : Grey

Chemical Form : Powder

Sika AnchorFix-3031

Price 579.0 INR / Pack

Minimum Order Quantity : 100 Packs

Usage & Applications : Construstion

Color : Part A: Off white Part B: Grey Mixed (A+B): Light grey

Chemical Form : Waterfroofing and Construstion

Purity : Very High

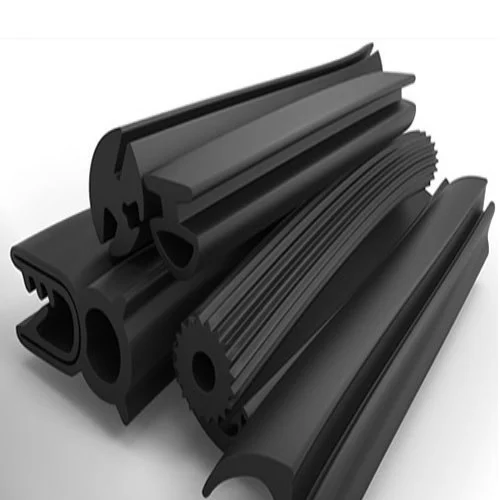

Extruded Rubber Products

Price 1200.0 INR / Meter

Minimum Order Quantity : 100

Usage & Applications : Waterproofing

Color : Black

Purity : High

We deal only in bulk orders.

Send Inquiry

Send Inquiry